Embroidery Digitizing for Hats | What Makes It Different

Table Of Content

- Understanding the Basics of Embroidery Digitizing for Hats

- Embroidery Hats and Caps are the Most Popular for Embroidery

- Baseball Caps

- Snapback Caps

- Trucker Hats

- 5-Panel and Fitted Caps

- Flat bill Caps

- Bucket Hats

- Cowboy Hats & Fashion Styles

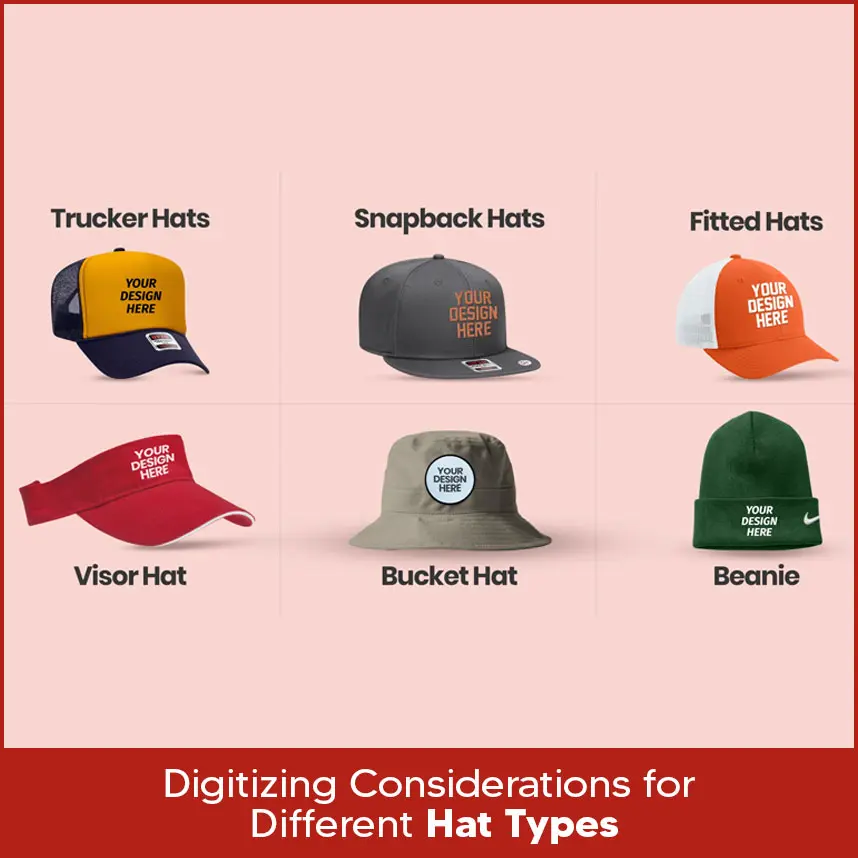

- Digitizing Considerations for Different Hat Types

- Structured vs Unstructured Caps

- Stretch Fabrics (like Beanies)

- Thick Brims and Panels (like Cowboy & Snapbacks)

- Mesh Backs (Trucker Hats)

- Best Placement Options for Hat Embroidery Designs

- Front Panel

- Side Panel

- Back Panel

- Brim / Visor

- Summary

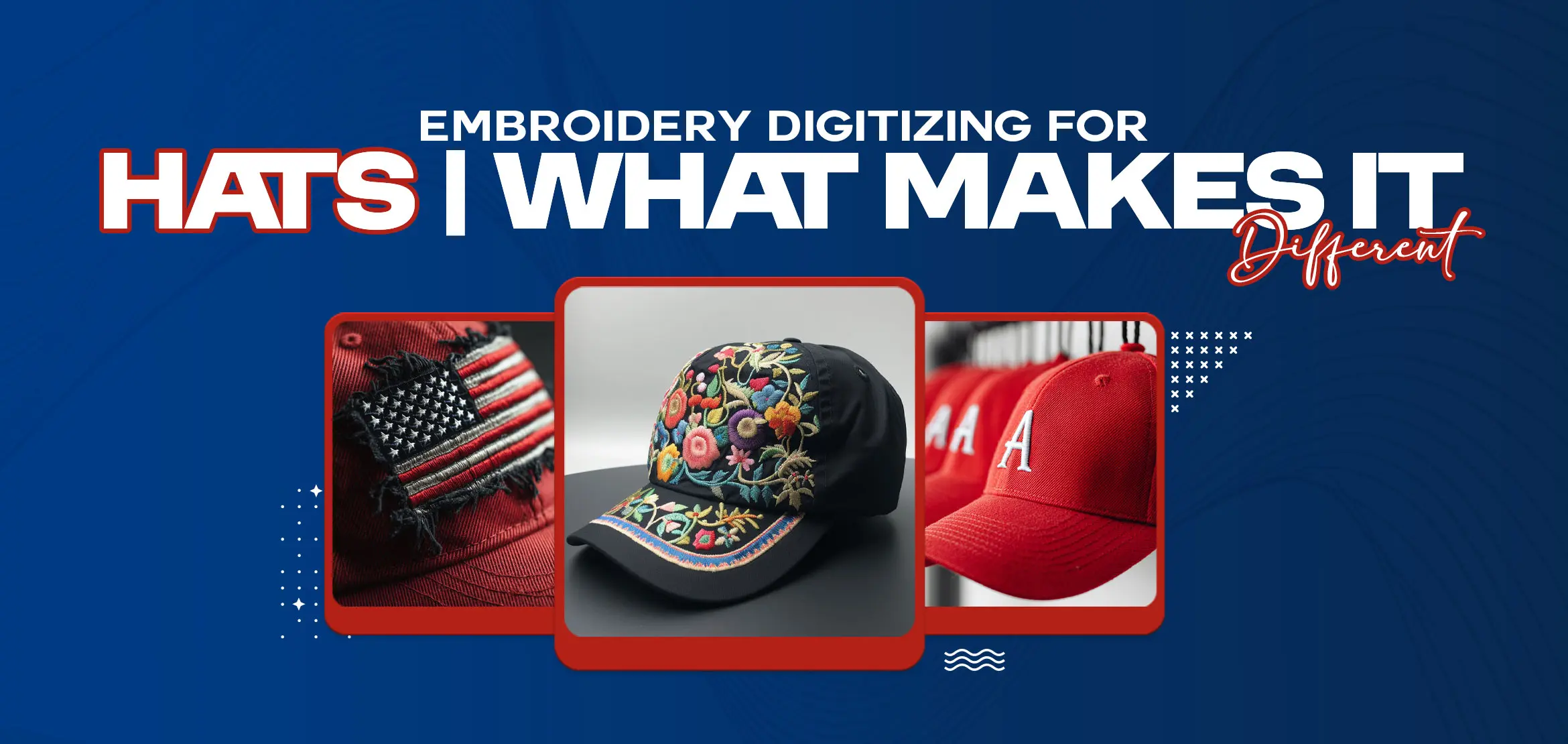

As you know that embroidery on hats looks sharp, attractive & eye catchy but the process of digitizing for hats is very different from digitizing for other fabrics. There are curves, seams and more structured features on a cap or beanie that complicate the process. Unless the design is digitized in the right way, the stitches can break, the embroidery will not be even on the surface, or the letters will be distorted. That’s why embroidery digitizing of hats needs proper planning, techniques and knowledge of how every type of hat responds to stitches. So let’s start with the basics, also discuss the most popular hats for embroidery and the factors that make hat digitizing different.

Understanding the Basics of Embroidery Digitizing for Hats

Basically embroidery digitizing for hats means converting a logo, design, or any other artwork into stitch files that an embroidery machine can read easily. Unlike flat garments such as t-shirts, hats have curved and stiff surfaces, which limit the design area.

Here are a few things that make hat digitizing attractive and unique:

Size Limitation: Many hats are embroidered with smaller designs, particularly on the front panel. Center-out Technique: Stitches are usually started in the middle of the cap and work outward in order to avoid puckering. Stabilizer: To hold the design in position, hats need support known as stabilizers. Needle and thread: Thicker fabrics might need stronger needles and threads. If you understand these basics, your design will look neat and attractive. Hats are made in different shapes and styles and use different materials, each style is meet to embroidery differently. These differences are important in selecting the appropriate hat because you want to look clean and avoid frequent mistakes. The following are some of the most popular hats and caps, which are used in embroidery nowadays: When we talk about hat embroidery, the first thing that comes to our mind is baseball cap embroidery. Their front panels are well structured to provide a stable surface upon which they can stitch, makinglogos look sharp and professional. These caps are common all over the world, especially in sports and business, and even in informal clothing. The snapback has a flat brim and an adjustable snap at the back. Their front is well structured and therefore, embroidery is visible. They particularly work well with street wearers and young generations who prefer a more modern look. Trucker hats are distinguished by a mesh back and foam on the front. The designs are usually only on the front of the foam because the mesh cannot be stitched. Because of their lightweight design, they have become popular for casual wear and marketing. Fitted caps lack an adjustable band, which is commonly used in sports and fashion. They have a sleek, polished look. Because the front panel of five-panel hats lacks a middle seam, extra space can be made for larger or more complex designs, making them ideal for embroidery. Snapbacks and flat bill caps are similar, although the brim of the snapback is smoother. They are popular and are frequently used for outstanding logo designs. The cap's solid structure means that the embroidery will be unique and clear. Bucket hats have a round crown and a downward brim. Because of the curved shape, embroidery placement can be tricky. Small logos are usually added to the front crown for the best results. Cowboy hats or wide-brimmed hats, and other fashion styles are less common for embroidery but still possible. The reason is that they are made with thick materials and curved shapes, embroidery is usually limited to small, simple designs that do not affect the structure of the hat. Structured caps have a stiffer front that holds embroidery firmly. Unstructured caps like dad hats need looser stitch density to avoid warping. Stretchy materials need flexible stitch patterns so the design can move without breaking when the fabric stretches. Thicker fabrics may need stronger needles and thread, along with proper underlay to prevent thread breaks. Embroidery does not work well directly on mesh. Most designs are digitized only for the foam or fabric front panel. Design placement is key in hat embroidery. Here are the most common spots: The most popular placement for logos, initials, and brand names. Works best for bold, centered designs. A great spot for small text or secondary logos. Common in promotional caps. Often used for slogans or small symbols. Works well with adjustable straps. Not common but stylish. Simple text or outlines can be placed on the brim edge. Do you want embroidery designs on your hats that look attractive or have bulk orders for a sports team or something else? If you are looking for hat embroidery digitizing services across the USA, then reach out to us because Digitizing USA is here for you. We provide embroidery digitizing services at affordable rates in the USA without any hidden charges. And if you want different embroidery digitizing services for shirts, jackets or others, we have got you covered. So don't waste your time and place an order now. So we understood that digitizing embroidery for hats involves more than just turning a pattern into stitches. The first step is understanding the challenges caused by curved, structured, or stretchable surfaces. Every style, from beanies and cowboy hats to baseball caps and snapbacks, needs a unique digitizing strategy. You can get clean, polished results by picking the appropriate method, customizing for fabric type and picking the right placement. Proper hat embroidery digitizing means your design will look fabulous and last for a long time, whether you're doing a small design on a beanie or a bold logo on a snapback.Embroidery Hats and Caps are the Most Popular for Embroidery

Baseball Caps

Snapback Caps

Trucker Hats

5-Panel and Fitted Caps

Flat bill Caps

Bucket Hats

Cowboy Hats & Fashion Styles

Digitizing Considerations for Different Hat Types

Structured vs Unstructured Caps

Stretch Fabrics (like Beanies)

Thick Brims and Panels (like Cowboy & Snapbacks)

Mesh Backs (Trucker Hats)

Best Placement Options for Hat Embroidery Designs

Front Panel

Side Panel

Back Panel

Brim / Visor

Summary