What is Embroidery Underlay in Embroidery Digitizing

Table Of Content

- Importance of Embroidery Underlay

- Stability and Preventing Distortion:

- Enhancing Design Definition:

- Reducing Thread Tension:

- Increasing Embroidery Speed and Efficiency:

- Improving Embroidery Durability:

- Types of embroidery underlay techniques

- Center Run Underlay:

- Zigzag Underlay:

- Parallel Underlay:

- Perpendicular Underlay:

- Contour Underlay:

- Fill Stitch Underlay:

- Traveling Underlay:

- Tips for using embroidery underlay effectively

- Understand Your Fabric:

- Consider Design Complexity:

- Use Multiple Underlay Techniques:

- Adjust Underlay Density:

- Match Underlay Stitch Direction:

- Test and Experiment:

- Pay Attention to Registration:

- Maintain Machine Maintenance:

- Examples of embroidery underlay in different designs

- Underlay Technique: Zigzag underlay.

- Underlay Technique: Center run underlay.

- Underlay Technique: Fill stitch underlay.

- Common mistakes to avoid in embroidery underlay

- 1. Using Incorrect Underlay Techniques:

- 2. Skipping Underlay Altogether:

- 3. Using Inadequate Underlay Density:

- 4. Neglecting Registration:

- 5. Overlapping Underlay Stitches:

- 6. Ignoring Machine Maintenance:

- 7. Not Testing Underlay Settings:

- Conclusion

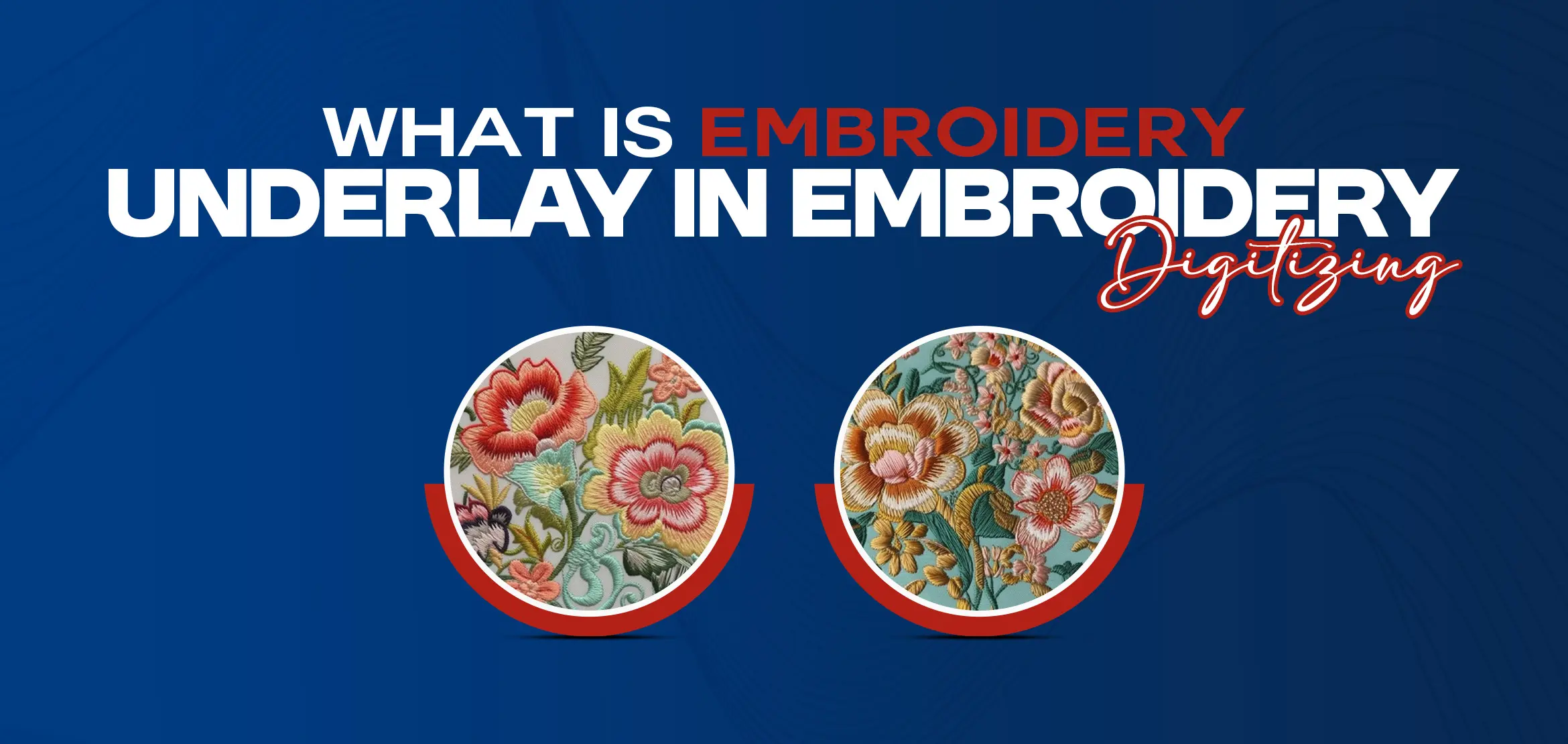

Embroidery underlay is a fundamental technique used in embroidery digitizing to provide stability and structure to the design. It involves stitching a base layer of stitches underneath the main elements of the design. There are different types of underlay stitches that can be used depending on the fabric type, design complexity, and desired outcome.

If you're new to this craft or simply curious about the technical aspects, you've come to the right place. In this article, we'll explore the concept of embroidery underlay and its role in creating beautiful and intricate designs.

Importance of Embroidery Underlay

Embroidery underlay plays a crucial role in ensuring the quality, durability, and appearance of embroidered designs. Here are some key reasons why embroidery underlay is important:

Stability and Preventing Distortion:

Underlay stitches provide a stable foundation for the embroidered design by securing the fabric to the backing material. This helps prevent distortion, puckering, or shifting of the fabric during the embroidery process, especially on stretchy or delicate fabrics.

Enhancing Design Definition:

Underlay stitches create a framework for the design, defining its shapes, edges, and details more clearly. This results in a sharper, more defined embroidered image or text, improving the overall visual appeal of the design.

Reducing Thread Tension:

By stabilizing the fabric and providing a solid base, underlay stitches help reduce the tension on the top stitches. This ensures that the top stitches lay smoothly and evenly over the fabric, avoiding bunching or looping of threads.

Increasing Embroidery Speed and Efficiency:

Properly executed underlay stitches can improve the efficiency of the embroidery process by reducing the number of trims and thread breaks required. This allows for faster production without compromising on the quality of the finished product.

Improving Embroidery Durability:

The additional support provided by underlay stitches helps increase the durability of the embroidered design. It reduces the strain on individual stitches, making the design more resistant to wear and tear over time.

Types of embroidery underlay techniques

There are several types of embroidery underlay techniques, each serving different purposes and suitable for various types of designs and fabrics. Here are some common types of embroidery underlay techniques:

Center Run Underlay:

Also known as a center walk underlay, this technique involves stitching a straight line down the center of the design area. It provides a stable foundation and helps define the centerline of the design, especially useful for large, filled areas.

Zigzag Underlay:

Zigzag underlay consists of stitching diagonal lines in a zigzag pattern across the design area. This technique adds stability to the fabric and helps prevent distortion while also creating texture, particularly suitable for designs with satin stitches or dense fill areas.

Parallel Underlay:

Parallel underlay involves stitching parallel lines adjacent to each other across the design area. This technique provides strong stability and prevents fabric distortion, particularly effective for designs with large, solid fill areas.

Perpendicular Underlay:

Perpendicular underlay consists of stitching lines perpendicular to each other across the design area. This technique provides additional stability and prevents fabric stretch, suitable for designs with intricate details or small text.

Contour Underlay:

Contour underlay involves stitching lines around the outer edges of the design, following its contours. This technique helps stabilize the fabric and define the shape of the design, particularly useful for designs with irregular shapes or complex outlines.

Fill Stitch Underlay:

Fill stitch underlay involves stitching a light density fill stitch or grid pattern within the design area. This technique provides a solid base for the top stitches and helps ensure even coverage, especially useful for designs with large, open areas or gradient fills.

Traveling Underlay:

Traveling underlay involves stitching continuous lines that travel across the design area, connecting various elements of the design. This technique provides stability and prevents gapping between stitches, particularly useful for designs with multiple elements or color changes.

Tips for using embroidery underlay effectively

Using embroidery underlay effectively is essential for achieving high-quality embroidered designs. Here are some tips to help you use embroidery underlay effectively:

Understand Your Fabric:

Different fabrics behave differently during the embroidery process. Understand the characteristics of the fabric you're working with, such as its stretchiness, thickness, and stability, to choose the most suitable underlay technique.

Consider Design Complexity:

The complexity of your design will influence the type of underlay you need. For intricate designs with small details, use underlay techniques that provide strong stabilization and prevent distortion, such as zigzag or parallel underlay.

Use Multiple Underlay Techniques:

Depending on the design, using multiple underlay techniques can provide optimal stabilization and coverage. Combine techniques like center run, zigzag, and contour underlay to ensure different areas of the design receive the appropriate support.

Adjust Underlay Density:

The density of your underlay stitches can affect the final appearance of the embroidery. For lighter fabrics, use lighter density underlay stitches to prevent them from showing through. For heavier fabrics, you may need denser underlay to provide adequate stabilization.

Match Underlay Stitch Direction:

Align the direction of your underlay stitches with the direction of your top stitches whenever possible. This helps maintain consistency and prevents the top stitches from pulling against the underlay, which could cause distortion.

Test and Experiment:

Before embroidering the final design, test different underlay techniques and settings on scrap fabric. This allows you to evaluate the results and make any necessary adjustments to ensure optimal stabilization and appearance.

Pay Attention to Registration:

Proper registration is crucial for aligning multiple elements within the design accurately. Use traveling underlay or other techniques to connect different elements and ensure they line up correctly.

Maintain Machine Maintenance:

Regularly maintain your embroidery machine to ensure it operates smoothly and produces consistent results. Clean the machine regularly, check tension settings, and replace needles as needed to avoid issues with underlay and overall embroidery quality.

Examples of embroidery underlay in different designs

Here are examples of embroidery underlay used in different types of designs:

Text Design with Zigzag Underlay:

Design: A company logo with text.

Underlay Technique: Zigzag underlay.

Description: The zigzag underlay is used beneath the text portion of the logo to provide stability and prevent distortion. It helps to maintain the shape and sharpness of the letters, especially in smaller font sizes.

Floral Design with Contour Underlay:

Design: A floral motif with intricate details.

Underlay Technique: Contour underlay.

Description: Contour underlay is applied around the outer edges of the floral design to stabilize the fabric and define the shape of the motif. It ensures that the delicate details of the flowers remain crisp and well-defined during the embroidery process.

Badge Design with Center Run Underlay:

Design: A badge or crest.

Underlay Technique: Center run underlay.

Description: Center run underlay is used across the entire badge design to provide a stable foundation and maintain the overall shape of the crest. It helps to prevent distortion and ensures that the intricate details and edges of the badge are embroidered accurately.

Geometric Pattern with Parallel Underlay:

Design: A geometric pattern with solid fill areas.

Underlay Technique: Parallel underlay.

Description: Parallel underlay is applied beneath the solid fill areas of the geometric pattern to provide stability and prevent fabric distortion. It ensures that the fill stitches lay evenly and smoothly, creating a clean and polished appearance.

Portrait Design with Fill Stitch Underlay:

Design: A portrait or photograph.

Underlay Technique: Fill stitch underlay.

Description: Fill stitch underlay is used throughout the portrait design to provide a solid base for the top stitches. It helps to ensure even coverage and prevents gaps or unevenness in the final embroidered image, especially in areas with varying shades and gradients.

These examples demonstrate how different underlay techniques can be applied to various types of designs to achieve optimal stabilization, definition, and overall embroidery quality.

Common mistakes to avoid in embroidery underlay

Avoiding common mistakes in embroidery underlay is crucial to ensuring the quality and durability of your embroidered designs. Here are some common mistakes to avoid:

1. Using Incorrect Underlay Techniques:

Using the wrong underlay technique for the fabric type or design can lead to inadequate stabilization or distortion. Make sure to select the appropriate underlay technique based on factors such as fabric stretchiness, thickness, and design complexity.

2. Skipping Underlay Altogether:

Skipping underlay altogether can result in poor stability, uneven stitches, and distortion of the design. Always include underlay stitches in your embroidery digitizing process to provide a solid foundation for the top stitches.

3. Using Inadequate Underlay Density:

Using underlay stitches with inadequate density can lead to insufficient stabilization and may cause the top stitches to sink into the fabric or appear uneven. Adjust the density of your underlay stitches based on the fabric type and design requirements to ensure optimal stability and coverage.

4. Neglecting Registration:

Neglecting proper registration between underlay and top stitches can result in misalignment and distortion of the design elements. Ensure that the underlay stitches are properly positioned and aligned with the top stitches to maintain consistency and accuracy in the final embroidered design.

5. Overlapping Underlay Stitches:

Overlapping underlay stitches excessively can create unnecessary bulk and stiffness in the design area, affecting the overall appearance and texture of the embroidery. Avoid overlapping underlay stitches unless necessary for specific design requirements.

6. Ignoring Machine Maintenance:

Neglecting regular maintenance of your embroidery machine can lead to issues such as inconsistent tension, skipped stitches, or thread breaks, which can impact the effectiveness of underlay stitches. Keep your machine clean and well-maintained to ensure smooth operation and consistent embroidery results.

7. Not Testing Underlay Settings:

Failing to test underlay settings and techniques on scrap fabric before embroidering the final design can result in unexpected outcomes and quality issues. Always conduct test runs to evaluate the effectiveness of your underlay settings and make any necessary adjustments before embroidering the actual design.

By avoiding these common mistakes and implementing best practices in embroidery underlay, you can ensure the stability, quality, and professional appearance of your embroidered designs.

Conclusion

Understanding the significance of embroidery underlay in digitizing is paramount for achieving high-quality embroidered designs. It provides stability, enhances definition, reduces tension, and boosts efficiency, ultimately ensuring durability and a polished finish. Whether you're crafting intricate florals or corporate logos, mastering underlay techniques is essential. To elevate your embroidery game, explore our embroidery services and digitizing expertise.

Don't miss out on optimizing your designs with proper underlay. Contact us now to transform your visions into impeccably embroidered reality! #EmbroideryServices#EmbroideryDigitizing