Why my needles are breaking on my embroidery machine

A machine will break needles every time if you do not pay attention. You need to observe and pay attention to the causes so that your needle does not break again. A common issue with embroidery machines is that the needle breaks when you are stitching the fabric. Needles can break in the embroidery machine because of the tension applied. This article explains how to correct this problem and keep your machine working efficiently.

Table Of Content

- Common Reasons Why Your Embroidery Needle Breaks

- Does the Needle Break Only When Sewing Backwards?

- Trouble with Needle Hitting the Machine Plate?

- Low Speed or Too Much Noise

- The Seams are Crooked

- The Fabric Slips or Resists

- The Thread Gets Tangled Under the Fabric

- Upper Thread Break

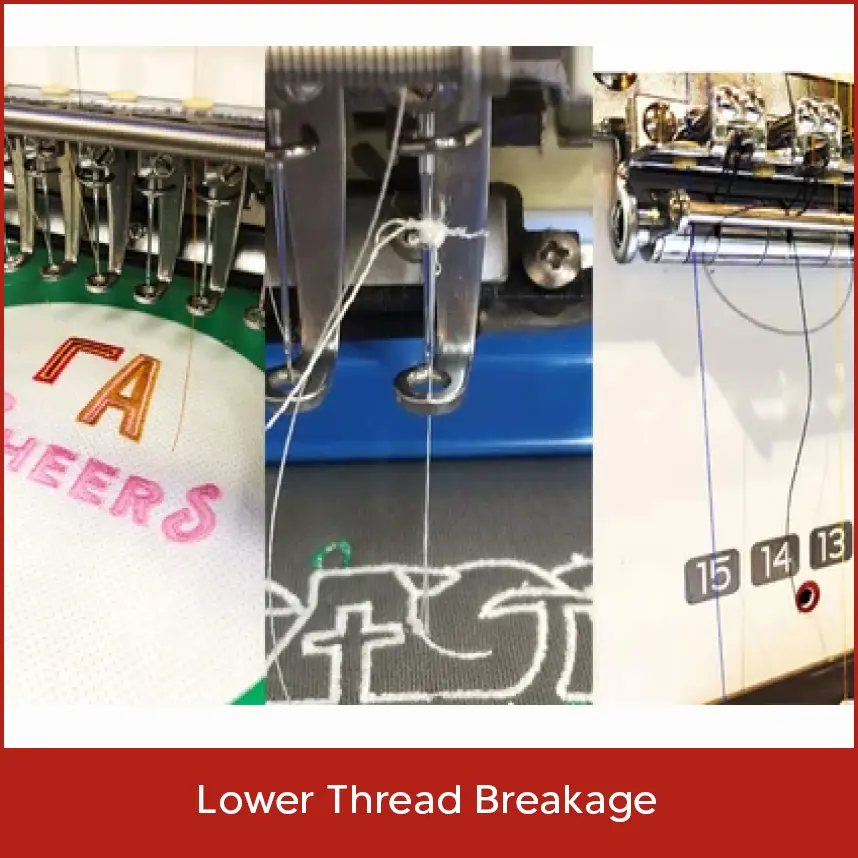

- Lower Thread Breakage

- Bonus Tips to Avoid Broken Needles in the Future

- Still Facing Needle Breakage or Thread Issues? Let Digitizing USA Help

- Conclusion

Here are a few reasons why your needle breaks: Do you use the appropriate needle for each fabric, e.g., needles for jeans or elastic fabrics? Do you use Schmetz needles? Check if the needle is well placed (flat side to the back and inserted all the way). Never pull on the fabric while sewing. Isn't the fabric too thick? If you can't easily pierce the fabric with a pin, then the machine won't either. Check out this more related blog post: Common causes of thread breaks in machine embroidery and solutions Then the needle is too fine or the fabric is too thick. Put the needle up first, then you can sew backwards. Always use the appropriate needle for each fabric, eg, needles for jeans/jeans, elastic fabrics. Never pull the fabric while sewing. Never sew backwards at full speed. Check if the needle is well placed (99% = flat side to the back). The needle only breaks when it hits something it can't go through so it must always be positioned correctly to be in line with the needle plate, you must take special care when pulling the fabric. This will ensure that the needle doesn't dislodge or fall out of alignment. Warning: If the needle breaks for some reason, then it is essential to collect all the pieces of the broken needle to prevent them from slipping through the mechanism and spoil the entire machine. The most normal thing is that these mishaps occur because the machine needs lubrication or slight basic maintenance adjustments. This can happen for two reasons: the presser foot is not applying the proper pressure and the fabric is not aligned as it should be. When the fabric is not aligned, most people make a mistake a try to pull it by hand, which could cause the needle to break. There is a trick to prevent fabrics from being unruly and that is to put a bit of masking tape at the base of the presser foot. Also called “bird's nest”, it arises when there is no tension on the needle thread to pull the thread from the bobbin. You can correct it by reinserting the machine and following the thread groove carefully. You have to ensure that the thread is fully engaged in the tension mechanism so that the needle won’t break. Upper thread breakage is one of the most common jams in embroidery machines and can result in broken needles. Make sure: The thread spool is placed correctly. The upper tension is not too tight. There are no knots or snags in the thread path. When the thread that gives us problems is the lower one, the first thing we should do is check that the thread is not caught in the bobbin capsule. Another cause could be the winding. If it is not done correctly or is so full that it does not turn well, it can also cause needle breakage. Change your needles regularly. A worn-out needle is more prone to breaking. Use proper embroidery backing/stabilizers to support the fabric. Slow down the speed when sewing complex patterns or dense designs. Always run a test stitch before starting a big embroidery project. If you're still experiencing problems like broken needles or thread tension issues even after applying all these solutions then it's time to say goodbye to the stress. Digitizing USA is here to make your embroidery projects smoother and error-free. We provide high-quality embroidery digitizing services at flat rates across the USA. We make sure that your designs are compatible with all embroidery machines. Therefore, don't allow technological difficulties to limit your creativity if you're a business owner or an individual. Let everything else go to Digitizing USA so you can concentrate on creating perfect designs. Say goodbye to broken needles and hello to flawless embroidery. Contact Digitizing USA today. Broken needles are so annoying, and one would not want to experience them at the peak of creating a meticulous piece. However, the nice part about it is that in the majority of cases, it is due to some simple reason: a broken needle, wrong fabric selection or even an alignment mistake. With a little closer observation of the way your machine is threaded, the kind of needle that you are using and how you are working with your fabric, several of the following common problems can be prevented.Common Reasons Why Your Embroidery Needle Breaks

Does the Needle Break Only When Sewing Backwards?

Trouble with Needle Hitting the Machine Plate?

Low Speed or Too Much Noise

The Seams are Crooked

The Fabric Slips or Resists

The Thread Gets Tangled Under the Fabric

Upper Thread Break

Lower Thread Breakage

Bonus Tips to Avoid Broken Needles in the Future

Still Facing Needle Breakage or Thread Issues? Let Digitizing USA Help

Conclusion