Best Thread Tension 101: A Guide for Embroidery Machines

Understanding thread tension is crucial to achieving high-quality embroidery results. Proper thread tension ensures that the stitches are balanced, with the top and bottom threads evenly interlocked.

In this article, we will discuss the factors that affect thread tension, such as thread type, needle size, and machine settings. We will also explore how to identify and troubleshoot common tension issues, like loose or tight stitches. By the end of this guide, you'll have a clear understanding of thread tension and how to adjust it to achieve professional-looking sewing projects.

Table Of Content

- What is Thread Tension?

- The Role of Bobbin Thread Tension

- How Thread Tension Issues Affect Embroidery Quality

- Factors Affecting Thread Tension

- Fabric Type and Thickness

- Thread Types and Weights

- Bobbin Thread Tensions

- Upper Thread Tensions

- Adjusting Thread Tension

- Identifying Thread Tension Problems

- Manual vs Automatic Thread Tension Adjustments

- Conclusion

- FAQs (Frequently Asked Questions)

What is Thread Tension?

Thread tension in embroidery refers to the balance and tightness of the threads in three areas: hoop tension, needle thread tension, and bobbin thread tension.

Hoop tension affects how the fabric is secured in the embroidery frame, while needle thread tension determines how tightly the top thread is pulled through the fabric.

Bobbin thread tension controls the tightness of the lower thread in relation to the top thread. Common signs of tension problems include loose or tight stitches, thread breakage, and puckering of the fabric.

Checking the tension settings, looking for any problems with the machine, and testing different tension settings on a test grid with varying stitch densities. Treatment may involve adjusting the tension settings, cleaning the machine, or replacing worn parts. Creating a test grid with different stitch densities is important for identifying optimal tension settings and ensuring high-quality embroidery.

The Role of Bobbin Thread Tension

The bobbin tension plays a crucial role in achieving proper embroidery and sewing machine stitches. It works in conjunction with the upper thread tension to ensure that the stitching is well-balanced and even. Proper bobbin tension is essential for preventing thread breaks and achieving high-quality embroidery. It also helps in adjusting thread tensions, so both the upper and lower threads work together seamlessly. In addition, having the correct bobbin tension ensures that the stitches are even and consistent. Resulting in a professional finish to any embroidery project.

Adjusting the bobbin thread tension is a simple process. Most embroidery machines have a small screw on the bobbin case that allows you to adjust the tension. When adjusting the tension, it's essential to test it on a scrap piece of fabric before starting your project. Start by loosening or tightening the screw slightly and then sewing a few stitches on the scrap fabric. Check the stitches to see if they are even and properly balanced. Continue making small adjustments until the stitches look uniform and free from any thread breaks or puckering. Once you have achieved the desired tension. You can be confident that your embroidery machine will produce high-quality stitches every time.

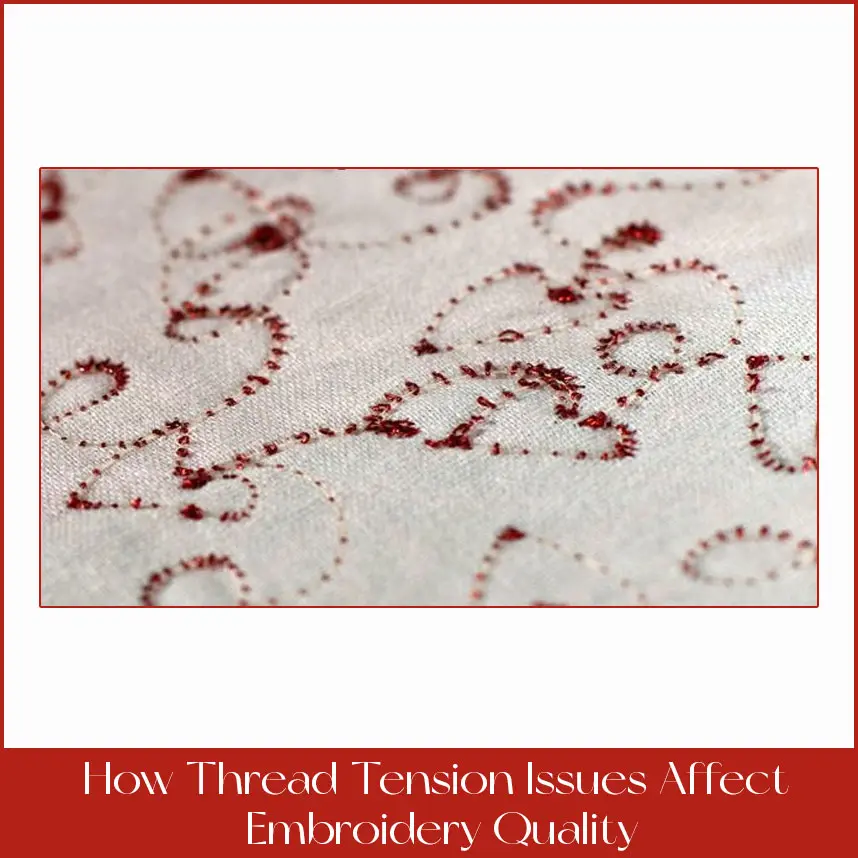

How Thread Tension Issues Affect Embroidery Quality

To adjust embroidery tension, first consider the type of thread and fabric being used. To test the tension, create a sample embroidery on a scrap piece of fabric and check for puckering or looseness in the stitches. If the tension is too tight, the fabric will pucker, and if it is too loose, the stitches will appear loopy. Regular tension checks should be performed as different thread and fabric types are used.

When adjusting embroidery tension, it is important to take into account the specific thread and fabric types being used. Thicker threads and heavier fabrics may require a tighter tension, while thinner threads and lighter fabrics may need a looser tension. It is crucial to test the tension on a scrap piece of fabric to ensure the stitches are not puckering or appearing too loose. By following these steps, tension issues in embroidery can be effectively addressed. Resulting in high-quality and professional-looking embroidery work.

Factors Affecting Thread Tension

Thread tension is a crucial element in achieving high-quality stitching and sewing. Several factors can influence the tension of the thread, which can lead to inconsistencies and problems with the finished product. Understanding these factors and how they affect thread tension is essential in producing professional and precise sewing projects. In the following headings, we will explore the various factors that can impact thread tension and how to address them to ensure smooth and even stitching.

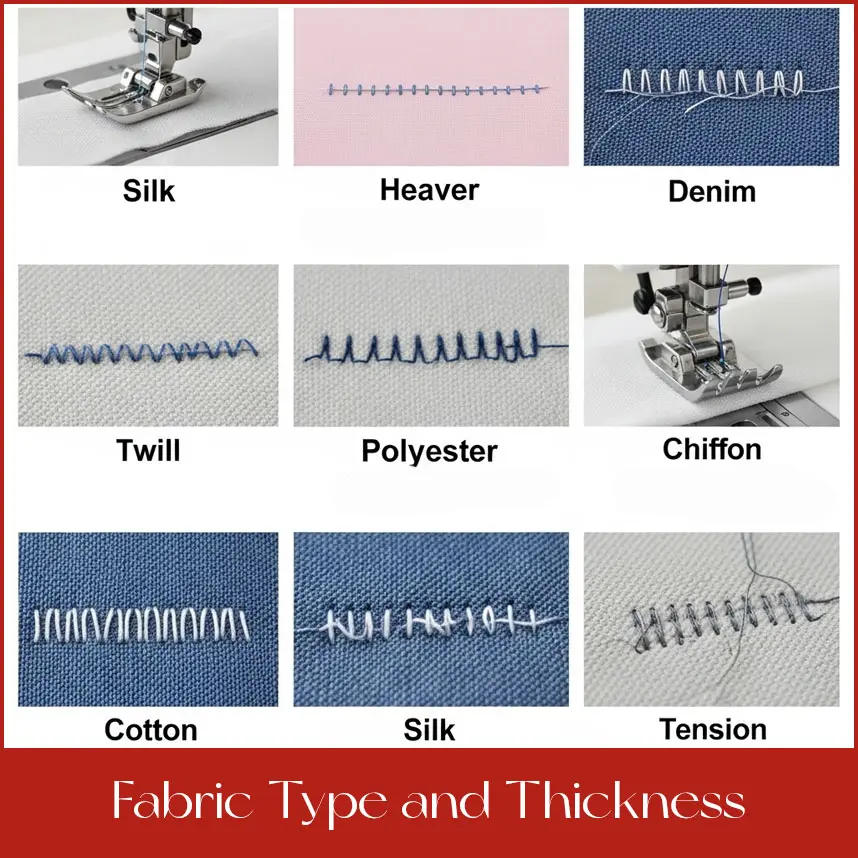

Fabric Type and Thickness

The type and thickness of fabric can significantly impact the thread tension settings on an embroidery machine. Delicate fabrics like silk require lighter tension to prevent the fabric from puckering or getting damaged. While heavier fabrics like denim may need slightly tighter tension to ensure the stitches hold up. Densely woven fabrics such as twill or canvas may require a higher tension setting to prevent loose stitches. While looser-weave fabrics like chiffon or lace may need a lower tension to avoid pulling and distorting the fabric. The top thread tension may need to be adjusted accordingly to accommodate the different fabric types and thicknesses.

In addition to fabric type and thickness, the type and weight of the thread being used also impact the tension settings.Different embroidery thread types, like cotton, polyester, or silk, may require slightly different tension settings to achieve the best results. It's essential to consider both the fabric and thread characteristics when adjusting thread tension on the embroidery machine to achieve the best stitching results for each project.

Thread Types and Weights

There are several thread types and weights commonly used in embroidery, including cotton, polyester, metallic, and nylon.

Cotton thread typically comes in various weights ranging from 30 to 50, while polyester thread can have weights ranging from 40 to 120. Metallic threads are often quite thin and can be delicate to work with, while nylon threads are known for their strength and durability.

Each type of thread may require different tension settings due to their unique characteristics.

For example, cotton threads have some elasticity, so using too much tension can cause the fabric to pucker. On the other hand, metallic threads are quite thin and can easily break if the tension is too tight.

Polyester threads are less elastic than cotton, requiring a balanced tension setting. Nylon threads, being quite strong, may need a higher tension setting.

Additionally, the storage of threads can impact tension behavior. Exposure to sunlight and extreme temperatures can cause threads to become brittle or stretched, affecting their elasticity and thickness, leading to tension issues during sewing.

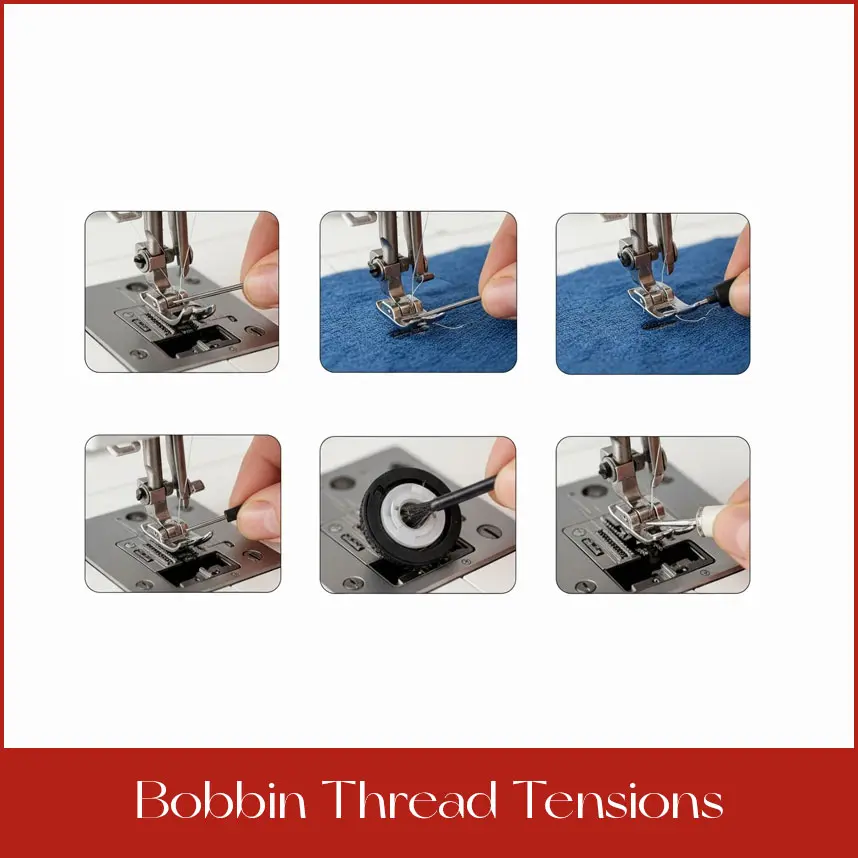

Bobbin Thread Tensions

The optimal tension for bobbin thread is essential for achieving good embroidery results. The recommended range for bobbin tension is between 25-35 grams, but it may vary depending on the type of fabric and thread being used. To adjust the bobbin tension, a small screw on the bobbin case can be tightened or loosened using a small screwdriver. Proper tension can be achieved by threading the bobbin correctly and making small adjustments while testing on a scrap piece of fabric. Maintaining the proper tension ensures clean and consistent stitching in embroidery.

In addition to adjusting the bobbin tension, it is crucial to keep the bobbin case clean to avoid any buildup of lint or thread residue. Regularly cleaning the bobbin case with a small brush and removing any debris will help maintain proper tension and prevent thread jams. By paying attention to the proper tension and maintenance of the bobbin case. The quality of embroidery work can be greatly improved.

Upper Thread Tensions

To adjust the upper thread tensions, start by referring to the default tension setting recommended in the machine's manual. Thread the machine and fabric with the same thread you will be using for your project. Use a sample pattern to test the tension. After sewing a few stitches, examine the stitches on the fabric and observe the visibility of the bobbin thread on the right side. If the bobbin thread is too visible and the upper thread is too loose, increase the tension slightly. If the bobbin thread is barely visible and the upper thread is too tight. Decrease the tension in small increments until you achieve the desired balance and a neat, even stitch.

Remember that the default tension setting recommended in the machine's manual is a good starting point. However, depending on the specific fabric, thread, and project you are working on, you may need to make slight adjustments to achieve the optimal upper thread tension. Always use a sample pattern to test the tension and adjust as needed based on the visibility of the bobbin thread on the right side of the fabric. By following these steps and paying attention to the bobbin thread visibility. You can ensure the upper thread tensions are adjusted just right for perfect stitches every time.

Adjusting Thread Tension

Proper thread tension is crucial for achieving well-balanced and professional-looking stitches in sewing. Whether you're dealing with too-tight or too-loose stitching. It's important to understand how to adjust thread tension on your sewing machine. This skill is essential for successfully working with different types of fabrics and achieving the desired results in your sewing projects.

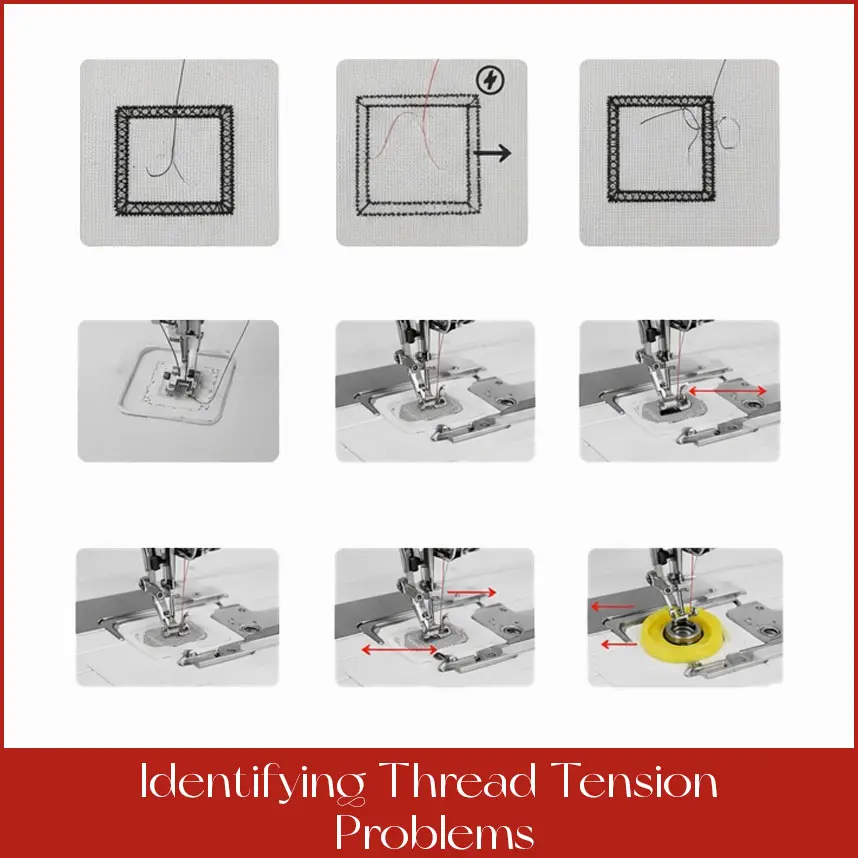

Identifying Thread Tension Problems

To identify tension problems, start by inspecting whether the bobbin thread is showing on top of the fabric. If the bobbin thread is showing on top, it indicates that the needle thread is too tight and the bobbin thread is too loose. If the bobbin thread is not showing on top, it may indicate that the needle thread is too loose. Check for looping of the needle thread or the bobbin thread pulling to the fabric's right side before making any adjustments. Before making any changes to the tension, it's important to clean the machine to remove any lint that may be affecting the tension. Additionally, oiling the machine ensures proper bobbin tension and needle tension. Allowing for smooth and consistent stitching without any tension problems.

In order to fix tension problems, it's crucial to identify the root cause of the issue by checking the positioning of the bobbin thread and the looping of both the needle and bobbin threads. After identifying the problem, it's recommended to clean the machine to remove any lint buildup that may be affecting the tension. Once the machine is clean, it's important to oil the machine to ensure proper bobbin tension and needle tension. This will help to prevent any future tension problems and keep the machine running smoothly. Regular cleaning and oiling of the machine are essential for maintaining proper tension and preventing issues with the bobbin and needle thread.

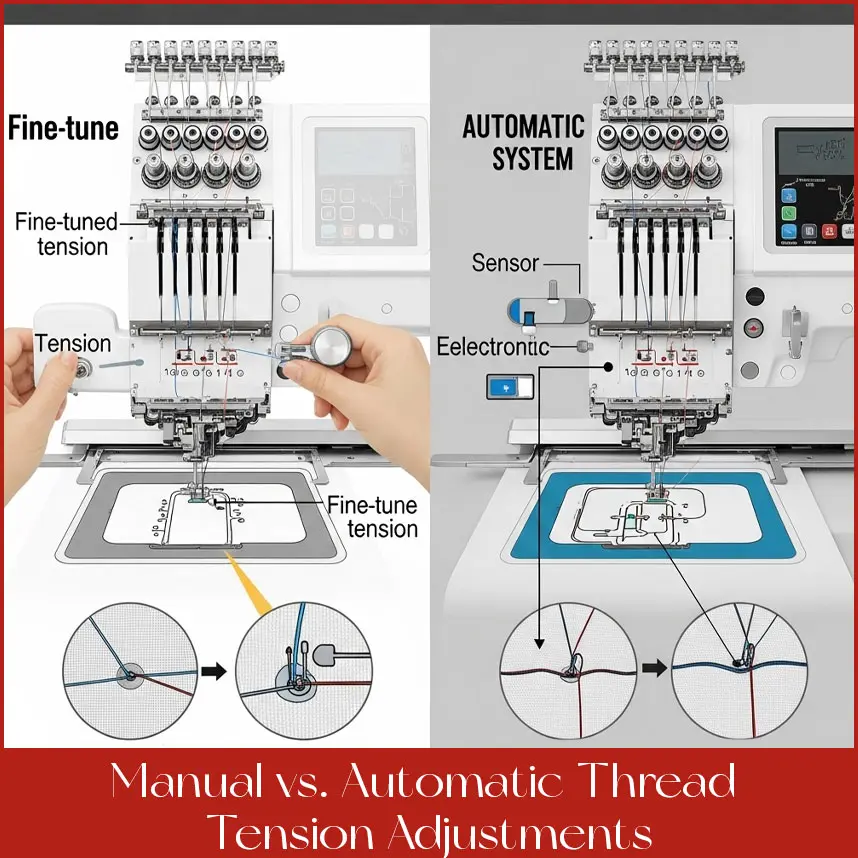

Manual vs Automatic Thread Tension Adjustments

Manual tension adjustments on an embroidery machine involve physically turning a dial or knob to adjust the tension of the upper thread. This gives the user precise control over the tension for different stitch types and fabric thicknesses.

Automatic tension adjustments, on the other hand, are controlled by the machine itself using sensors to detect the fabric thickness and adjust the tension accordingly. When adjusting embroidery machine tension manually. The user must consider the specific stitch type being used and the type of fabric being sewn in order to achieve the right level of tension. Automatic tension adjustments may be more convenient, but they may not always provide the same level of precision when sewing different fabrics or using different stitch types.

When manually adjusting tension for various stitch types and fabrics. The user must consider factors such as the thread type, needle size, and fabric thickness. This differs from automatic tension adjustments, where the machine makes these adjustments based on sensors and preset settings. Key factors to consider when deciding between manual and automatic tension adjustments for embroidery machine tension control include the level of precision needed for specific sewing projects. Personal embroidery expertise and the convenience of automatic adjustments versus the control of manual adjustments. Ultimately, the choice between manual and automatic tension adjustments depends on the user's specific sewing needs and preferences.

Conclusion

Achieving optimal thread tension is paramount for producing professional and high-quality embroidery work. This guide has provided comprehensive insights into the factors affecting thread tension. From fabric type and thickness to the various types and weights of threads. Understanding and adjusting bobbin and upper thread tensions are essential skills for every embroiderer.

Regular maintenance, including cleaning and oiling, ensures consistent stitching and prevents tension-related issues. For flawless embroidery results, consider our embroidery services. Our expertise and precision guarantee perfection in every stitch. Explore the art of embroidery with confidence and precision. Choose our embroidery services today.

FAQs (Frequently Asked Questions)

Q1. Why is understanding thread tension important in sewing?

Understanding thread tension ensures balance and even stitches.

Q2. What are the three areas of thread tension in embroidery?

Hoop tension, needle thread tension, and bobbin thread tension.

Q3. How do you adjust bobbin thread tension in a sewing machine?

Use a small screw on the bobbin case for adjustments.

Q4. What factors can affect thread tension in sewing?

Fabric type, thickness, thread type, and machine settings.

Q5. Why is regular cleaning and oiling important for tension?

Ensures proper bobbin and needle tension, preventing future issues.