Home Embroidery Machine vs Commercial Machine | Key Differences Explained

Table Of Content

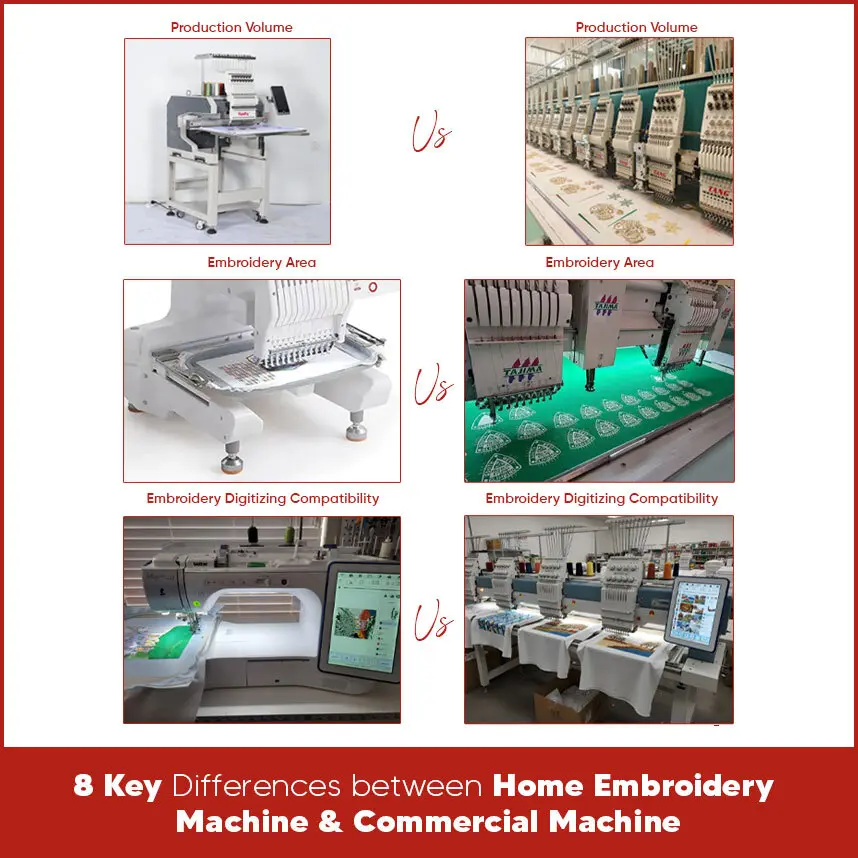

- How Do Home Machines Differ from Commercial Machines?

- Home vs Commercial Embroidery Machines (Quick Comparison)

- 8 Key Differences between Home Embroidery Machine & Commercial Machine

- 1. Cost

- 2. Production Volume

- 3. Speed

- 4. Durability

- 5. Embroidery Area

- 6. Versatility

- 7. Features

- 8. Embroidery Digitizing Compatibility

- Summary

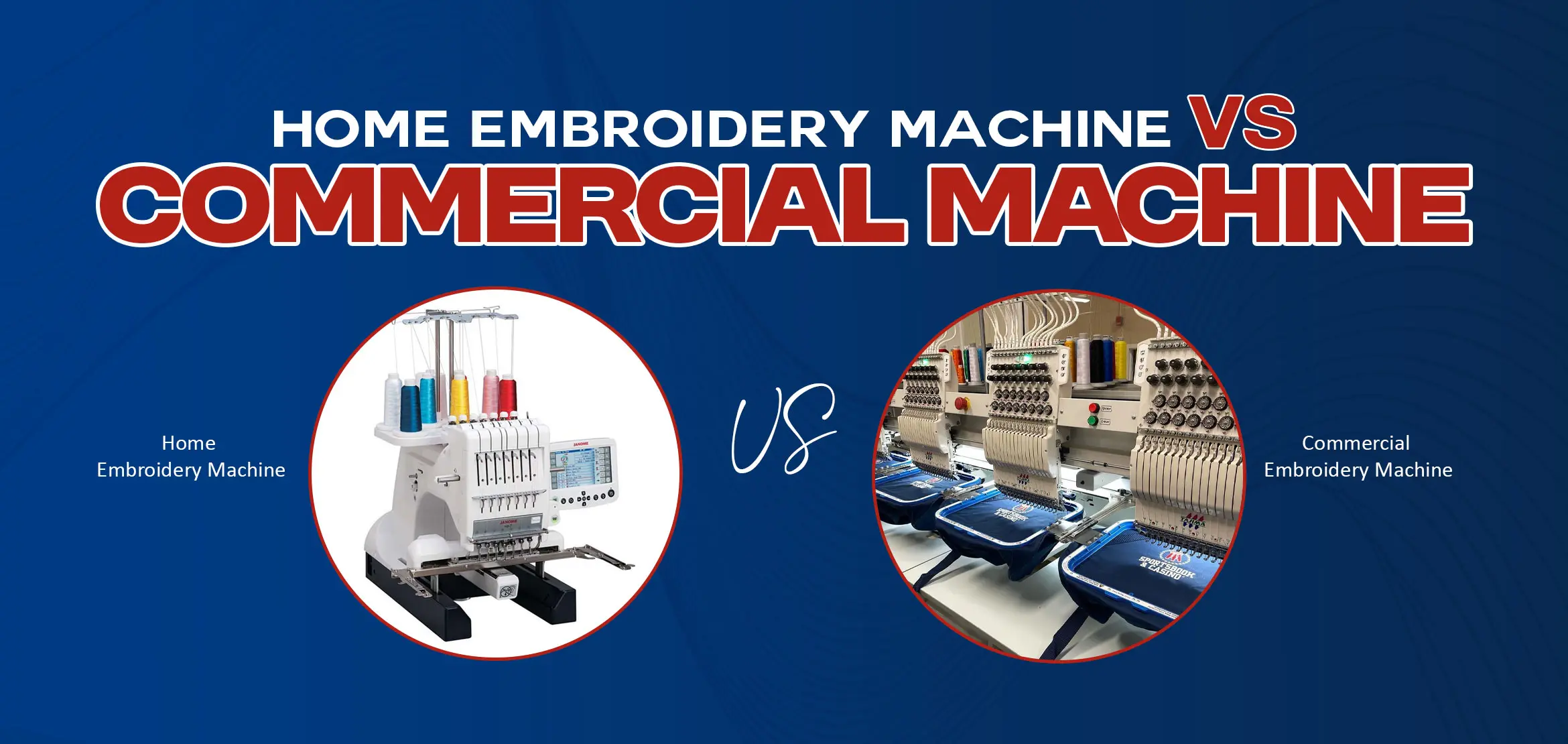

Are you planning to start embroidery work but one question comes first. Should I buy a home embroidery machine or a commercial machine? This question is so important because both machines have different purposes. Many people get confused because both machines stitch designs, logos, patterns, etc. However, they don't work the same way. They have major differences like in speed, production volume, output, and final results.

In this blog post, we will cover the actual differences between home embroidery machines and commercial embroidery machines. This guide also helps you choose the right option based on your needs & budget, as well as how embroidery digitizing fits into both setups. Home embroidery machines are made for personal use, small projects or startups. People use them for small businesses or learning embroidery at home. These machines have easy controls and simple operation. Manufacturers build commercial embroidery machines for production work. Businesses use them to manage bulk orders, meet deadlines, and complete professional embroidery projects. These machines are good at speed, accuracy, and long working hours. The difference goes beyond size. It depends on how much work the machine handles, how fast it runs, and how well it supports professional embroidery digitizing files. Cost stands as the first and most important difference. A home embroidery machine costs much less. It suits beginners, hobby users, and small startups. The price usually includes basic features and limited embroidery space. A commercial embroidery machine are costly than home embroidery machine. The higher price reflects better build quality, faster stitching, and long-term durability. Businesses treat this cost as an investment because the machine supports passive income. If you start as a small startup, a home machine is best. If you plan to accept large orders, a commercial machine becomes necessary. Production volume clearly separates these machines. A home embroidery machine handles low to medium workloads. It works well for a few designs each day. As long as the workload stays limited, the machine performs smoothly. A commercial embroidery machine handles high production volume. It runs for many hours without stopping. That's why businesses complete bulk orders for caps, shirts, jackets and more. If you plan to grow your embroidery business, production volume plays a key role. Speed affects delivery time and business growth. Home embroidery machines stitch at slower speeds. This pace helps beginners maintain control and reduce mistakes. Commercial embroidery machines stitch at much higher speeds. They complete designs quickly while keeping stitch quality consistent. This speed saves time and increases output. Fast machines perform best when they use clean and properly prepared embroidery digitizing files. Durability determines how long a machine lasts. Manufacturers use lighter materials in home embroidery machines. These machines work well for light use but they don't last long if you use them every day. Manufacturers use heavy-duty parts in commercial embroidery machines. These machines handle daily use without frequent breakdowns. This strength helps businesses avoid repair delays. If embroidery supports your daily work, durability becomes essential. Embroidery area limits design size. Home embroidery machines have smaller hoop sizes. These hoops work for small logos, names, and small designs. Commercial embroidery machines have larger embroidery fields. These fields allow bigger designs, jacket backs, and detailed patterns without splitting the design. Larger embroidery areas also reduce editing time during digitizing. Versatility controls what you can embroider. Home embroidery machines support common fabrics like cotton, denim, and light knits. They struggle with thick or hard materials. Commercial embroidery machines handle many fabric types, such as caps, leather,towels, and jackets. They support plain embroidery as well. This flexibility supports businesses in accepting more order types. Features improve control and efficiency. Home embroidery machines have basic features like: - Built-in designs. -USB support. -Simple screens. Commercial embroidery machines have advanced features like multiple needle options, automatic thread trimming, thread break sensors, advanced control panels, large embroidery area and many more. These features minimize mistakes and save time. Advanced features work best with well-digitized designs. Digitizing plays a major role in embroidery quality. Home embroidery machines need simple digitizing files. Complex designs cause thread breaks or poor stitch results. Commercial embroidery machines handle professional digitizing files with ease. They support dense stitches, fine details, and complex logos. For consistent results, businesses rely on an expert digitizing service provider to prepare files correctly. Your budget and needs decide the choice between a home embroidery machine and a commercial embroidery machine. If you want to learn embroidery, handle small projects, or run a side business, we will recommend a home embroidery machine. It keeps costs low and gives easy control. But if you are planning to run a professional embroidery business, managing bulk orders, a commercial embroidery machine is highly recommended. It gives you speed, durability, and strong support for bulk embroidery digitizing. No matter which machine you use, high-quality digitizing controls the final result. Poor digitizing ruins output even on the best machine. For this reason, many professionals trust Digitizing USA for clean, accurate, and production-ready embroidery digitizing.How Do Home Machines Differ from Commercial Machines?

Home vs Commercial Embroidery Machines (Quick Comparison)

8 Key Differences between Home Embroidery Machine & Commercial Machine

1. Cost

2. Production Volume

3. Speed

4. Durability

5. Embroidery Area

6. Versatility

7. Features

8. Embroidery Digitizing Compatibility

Summary

If you want smooth stitching, fewer errors, and professional results, Digitizing USA prepares your designs correctly from the start. Contact Digitizing USA today and make every stitch count.