Why Vector Tracing is a Must for Screen Printing?

Table Of Content

- Understand Step-by-Step: Why Vector Tracing Is a Must for Screen Printing

- Scalability without quality loss

- Clean lines and sharp edges

- Color separation made easy

- Reduced file size and easier edits

- Universal compatibility with printing hardware

- Essential Tools and Software for Vector Tracing in Screen Printing

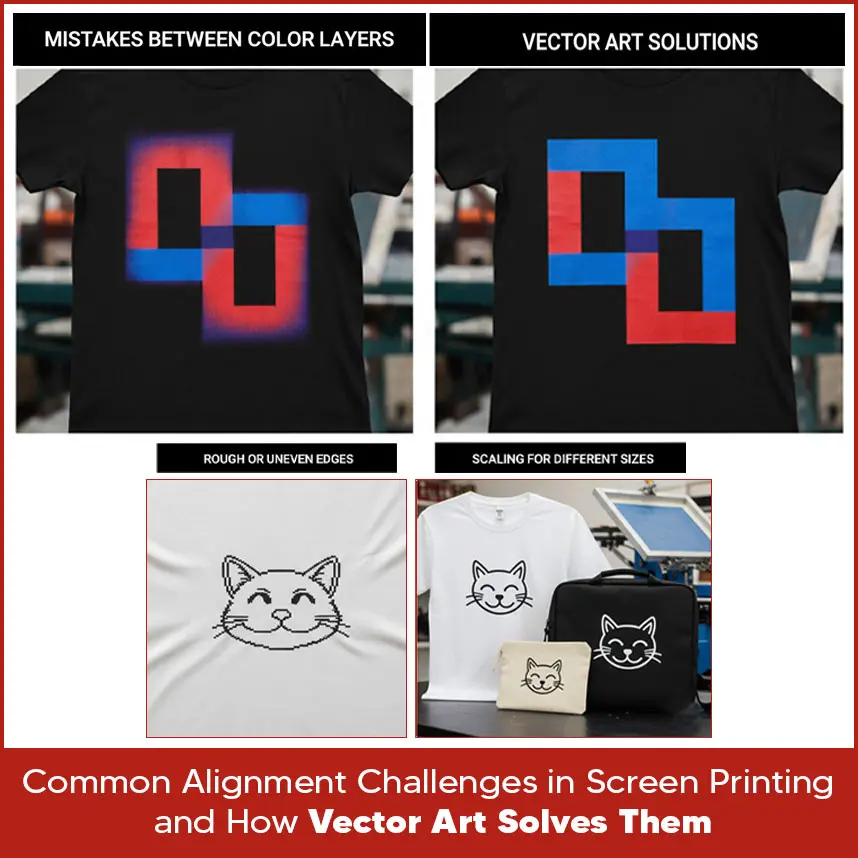

- Common Alignment Challenges in Screen Printing and How Vector Art Solves Them

- Mistakes between color layers

- Distortion when stretching fabric

- Rough or uneven edges

- Difficulty in scaling for different print sizes

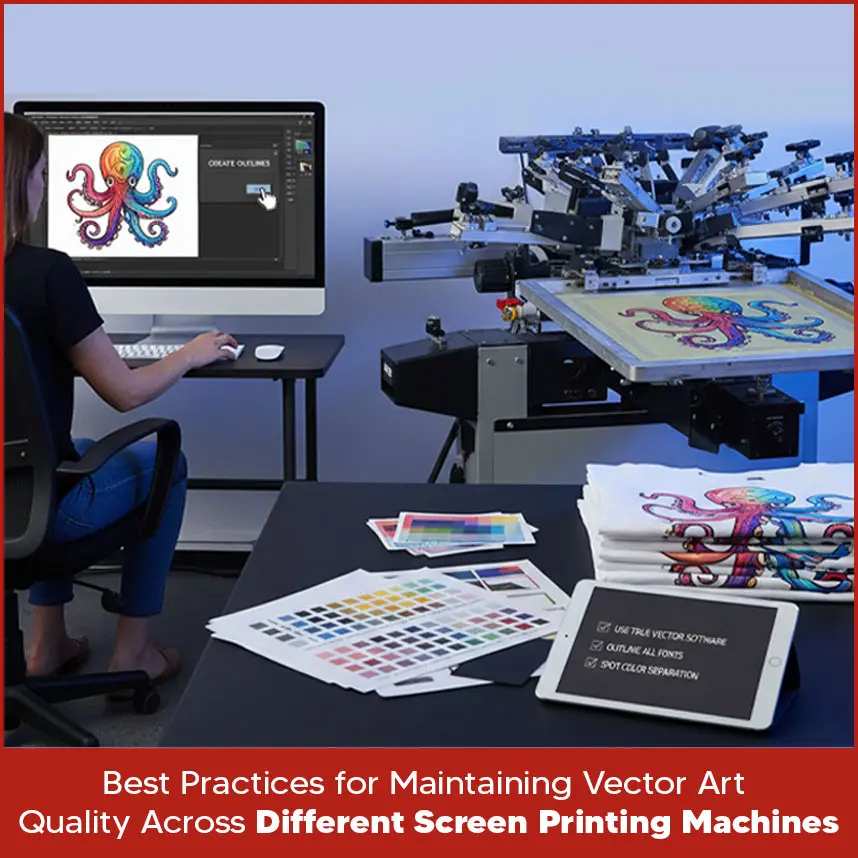

- Best Practices for Maintaining Vector Art Quality Across Different Screen Printing Machines

- Innovative Techniques in Vector Tracing to Enhance Screen Printing Design Details

- Summary

Suppose you have to design a logo or other artwork you love, send it to your printer but what you see the final print, it turns out blurry, jagged or misaligned. Ah, it is so frustrating.

In screen printing, the most important thing is clarity and perfection. That’s why vector tracing for screen printing becomes essential. With vector tracing, your design can be enlarged, shrunk or edited without losing sharpness. It makes sure every line, curve and color separation remains clear. If you want your prints to look professional and last, vector tracing is not just helpful, it’s a must!

Now let's move on and understand this guide.

Understand Step-by-Step: Why Vector Tracing Is a Must for Screen Printing

Let’s break down exactly why vector tracing is so important in screen printing. Check it out step by step.

Scalability without quality loss

Vector images are based on mathematical formulas such as points, lines and curves. As a result, they remain sharp if you scale them up or down to any size.

You want that sharpness without compromising quality when screen printing, then no matter your design is placed, on a banner, on a pocket logo or somewhere else.

Clean lines and sharp edges

When preparing for screen printing, you need sharp outlines and precise shapes. Vector tracing ensures there’s no pixelation, fuzziness or stair-stepped edges. The printer sees exact paths to follow.

Color separation made easy

Screen printing usually involves separating each color into its own screen. With vector art, each shape and area is distinct, which makes separating colors much simpler and more accurate.

Reduced file size and easier edits

Because vectors don’t store pixel by pixel data, files remain relatively compact. Also, making changes (like altering a curve or changing a color) is much easier than editing a raster image.

Universal compatibility with printing hardware

Printers and prepress machines expect vector files (AI, EPS, SVG, PDF) for optimal results. Using raster images usually causes delays, printer rejections or extra charges.

Because of all these steps and reasons, vector tracing becomes indispensable for any serious screen printing project.

Essential Tools and Software for Vector Tracing in Screen Printing

To do vector tracing well, you need reliable tools. Here are some of the standard software and tools used in the industry:

- Adobe Illustrator: Adobe Illustrator is an industry standard. It has detailed control over paths, anchor points, curves and color separation. - CorelDRAW: Popular among many designers, especially for vector illustration and print ready design. - Inkscape: A free & open-source alternative that’s quite capable, especially for simpler designs. - Affinity Designer: A powerful & budget friendly software that combines vector capabilities with easy to use interface. - Vector tracing plugins / auto-trace tools: Some software programs have “auto trace” features but these are best used only on simpler designs. Manual tracing is usually required for high quality. When you combine the right tool with skill, your vector tracing becomes a strong base for flawless screen prints. Screen printing involves multiple steps, each requiring tight alignment and precision. Here are some challenges and how vector art helps: If your color layers are not perfectly aligned, prints get blurry or colors bleed. Vector paths ensure every shape lines up perfectly. When printing on fabrics that stretch (like T-shirts), raster images can distort at edges. Vector art adapts better to transformations. Without vector tracing, curves and diagonal lines show uneven edges. Vector paths keep edges smooth regardless of size. If you have a single design and want to put it on different items like a shirt and a laptop bag, raster versions may need multiple edits. Vector files can be adjusted easily without redoing the art. Because vector art handles these alignment and scaling challenges elegantly, it becomes a practical solution in real-world printing environments. Every printing machine has its quirks, mesh size, ink thickness, screen tension and substrate (fabric, paper, etc.). To ensure your vector artwork remains sharp across various setups, follow these best practices: - Use appropriate path simplification: Don't add too many anchor points to the vector. Keep the paths clean and simple. - Maintain minimum line thickness: For very thin lines, make sure they remain printable. Test that they don’t disappear under mesh or ink spread. - Convert text to outlines/curves: This ensures font compatibility across machines. - Use consistent vector formats: Provide AI, EPS, or PDF. Avoid raster bits inside vector files. - Check for stray nodes or open paths: These can cause printing errors or gaps. - Adjust for mesh and ink spread: Slight modifications may be needed for heavier inks or coarse meshes. If you are looking for reliable vector tracing services for screen printing, Digitizing USA is ready to assist. We offer vector tracing at competitive rates without compromising on accuracy. If you’ve been searching for low-cost vector tracing solutions, Digitizing USA is your best choice. Contact us now and get professional vector tracing services from anywhere in the world, at affordable prices. Here are some advanced techniques you can apply to get an edge in your designs: - Using curves with controlled handles to shape smooth transitions. - Combining manual tracing with auto-trace, let auto-trace do heavy lifting on simple parts and refine manually. - Variable stroke width: Give lines subtle changes for aesthetic effect while staying printable. - Adding micro-details carefully: Small dots, thin lines but always test if they print well. - Shading with small dots or patterns: Instead of gradients, use dots for smooth transitions. - Layer masking in vectors to hide or reveal parts without altering original paths. - Smart color substitution: Keeping spot colors isolated for easier changes. Using these techniques, your vector art won’t just survive printing, it will shine through in detail and precision. Vector tracing is more than a design step, it’s the backbone of high-quality, professional screen printing. From scalability, clean edges and color separation to compatibility and low file weight, vector art brings everything screen printing needs into one format. If you’re ready to get top-tier vector tracing/raster to vector conversion services without overspending, Digitizing USA is here to help. Reach out today and we’ll deliver accurate, print-ready vector art from anywhere in the world. Let’s make your screen printing designs flawless. Contact Digitizing USA now and transform your designs into print-ready perfection.Common Alignment Challenges in Screen Printing and How Vector Art Solves Them

Mistakes between color layers

Distortion when stretching fabric

Rough or uneven edges

Difficulty in scaling for different print sizes

Best Practices for Maintaining Vector Art Quality Across Different Screen Printing Machines

Innovative Techniques in Vector Tracing to Enhance Screen Printing Design Details

Summary